DISTRIBUTION CENTRAL

AREAS OF APPLICATION

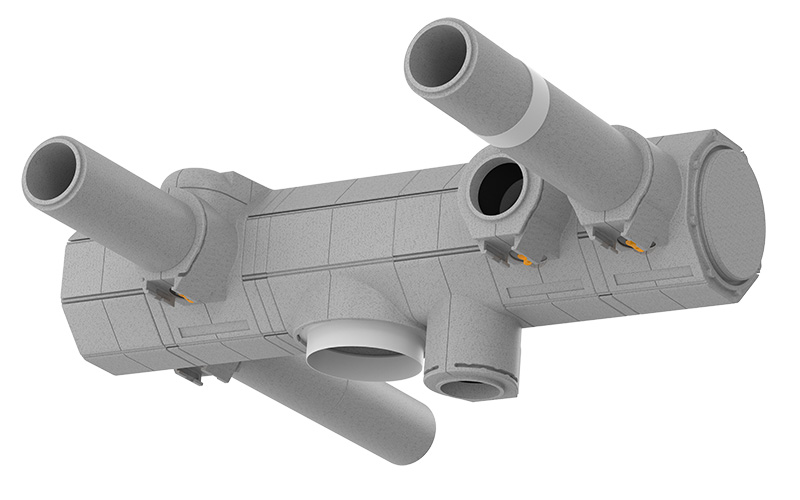

The air-lab modular distributor is designed for central air distribution within the utilities room.

It works by feeding the incoming and outgoing air for a specific zone to at least one

modular distributor, which then distributes this air to the piping system.

PRODUCT DESCRIPTION

This distribution system has a modular structure and therefore permits infinite configurations.

All of the exterior casing parts are made of EPP, which provides effective thermal insulation.

The module interfaces are designed in such a way that the system pipes can be connected

within a 45 degree grid along the distributor shaft.

This means that every distributor can be configured in whatever way is best suited to the

conditions on site, including in areas with limited space.

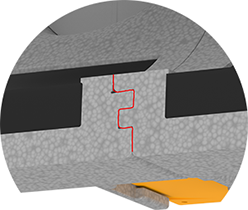

The individual modules feature double tongue and groove connections that interlock with each other.

They are furthermore sealed in two ways (with seals and adhesive), which makes them

extremely leak-proof and strong.

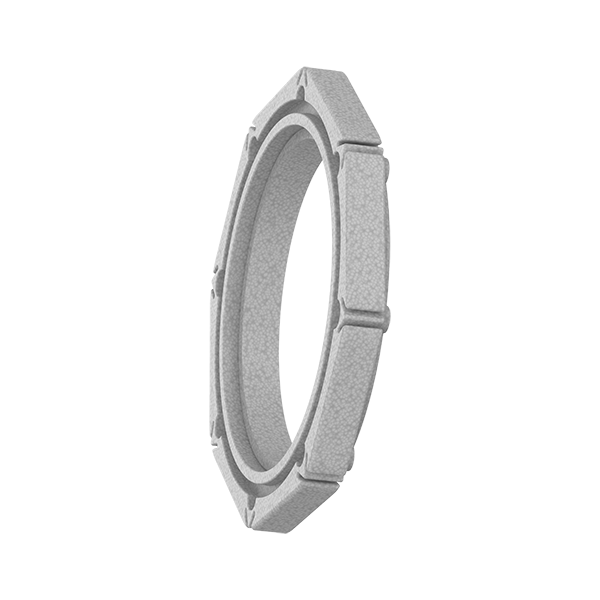

Spacer ring K/K

Combined distributor module

Pipe section

Spacer ring K/S

Bypass module

Pipe section

Cover

Spacer ring K/S

Double sleeve

Combined distributor module

Feed module

Cover

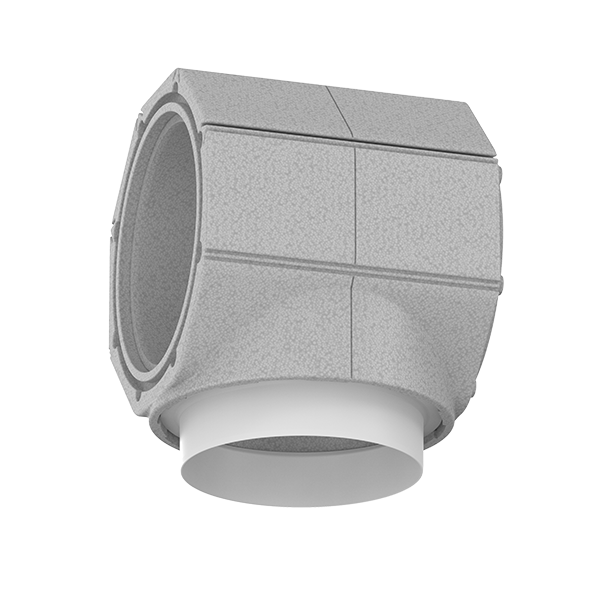

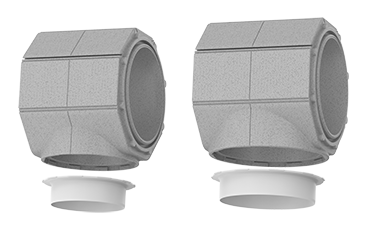

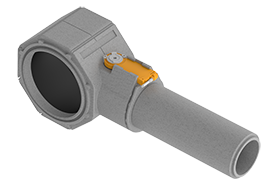

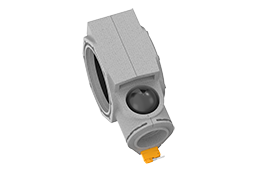

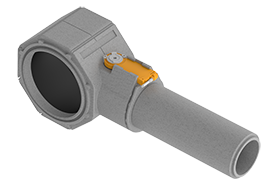

FEED MODULE

The feed module is designed for connecting incoming and outgoing air pipes.

Double tongue and groove connection

i

Feed module 160 / Feed module 200

The flange connection has a bayonet lock, which means it can be fitted to the feed module without any tools.

i

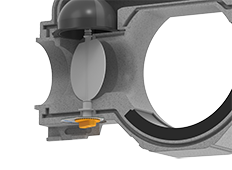

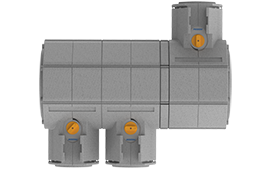

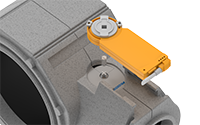

COMBINED DISTRIBUTOR MODULE

The combined distributor module is designed to distribute and regulate air flow to the

individual incoming and outgoing air pipe sections.

It features an integrated throttle valve that adjusts the module’s internal cross section to control air flow.

The combined distributor module is furthermore fitted with an acoustic foam insert in the

distribution shaft and pipe interface area in order to reduce noise.

SPACER RING K/S

The K/S spacer ring is designed for adjusting the gap between two distributor modules.

BYPASS MODULE

The bypass module fulfils the same function as the combined distributor module

but is fitted with a second mechanically-coupled flow restrictor.

This flow restrictor (bypass) can be used to introduce supply air into a single room

at a different temperature.

The bypass module is furthermore fitted with an acoustic foam insert inside the

distribution shaft.

Throttle valve

i

Double tongue and groove connection

i

Tongue and groove connection for connecting the pipe section

i

Acoustic foam insert

i

Acoustic foam insert

i

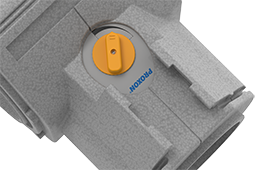

Dial for adjusting the throttle valve

Connector for electrical actuator

i

Throttle valve

i

Double tongue and groove connection

i

Bypass section with

connection at the back

Alternative: Bypass section

with connection at the front

i

Acoustic foam insert

i

Dial for adjusting the throttle

valve and flow restrictor

Connector for electrical

actuator

i

Flow restrictor (bypass)

i

Tongue and groove connection for connecting the pipe section

i

i

SPACER RING K/K

The K/K spacer ring is used to make the distributor modules point in different directions

while ensuring that all of the throttle drives are on the same side.

i

COVER

The cover is used to seal off both or either side of the distribution shaft.

PIPE SECTION

The pipe sections are designed for use as air ducts within utility rooms.

The individual sections can be joined to form longer pipes by their key and slot connections.

i

Key and slot connection for connecting a pipe section to a combined distributor or bypass module

Alternative: Key and slot connection for connecting

another pipe section

i

DOUBLE SLEEVE

The double sleeve is designed for connecting two pipe sections that have been shortened.

Connector for a shortened pipe section

i

TECHNICAL DATA

Series

Type

Length

Width of grid (B)

Height

Connection diameter

Distribution shaft diameter

Throttle valve

Operating temperature

Firerating

Feed Module

160

Art. no. 70285

320

225

270

160

200

0

STL-25/STH+100

5.1 (not readily flammable)

Feed Module

200

Art. no. 70284

320

250

270

200

200

0

STL-25/STH+100

5.1 (not readily flammable)

Combined

Distributor Module

Art. no. 70286

380

175

270

100

200

1

STL-25/STH+100

5.1 (not readily flammable)

Bypass Module

Art. no. 70287

380

175

270

100

200

2

STL-25/STH+100

5.1 (not readily flammable)

Unit

mm

mm

mm

mm

mm

Number

°C

Series

Type

Length

Width of grid (B)

Height

Distribution shaft diameter

Operating temperature

Firerating

Spacer ring K/S

Art. no. 10523

270

25

270

200

STL-25/STH+100

5.1 (not readily flammable)

Spacer ring K/K

Art. no. 10546

270

25

270

200

STL-25/STH+100

5.1 (not readily flammable)

Cober

Art. no. 10524

215

20

215

200

STL-25/STH+100

5.1 (not readily flammable)

Unit

mm

mm

mm

mm

°C

Series

Type

Length

External diameter

Internal diameter

Operating temperature

Firerating

Pipe section

Art. no. 10525

325

130

100

STL-25/STH+100

5.1 (not readily flammable)

Double sleeve

Art. no. 10526

50

130

98

STL-25/STH+100

5.1 (not readily flammable)

Unit

mm

mm

mm

°C

ACCESSORIES

● Installation kit (Art. no. 70288)

Installation example:

● Shaft extension (art. no. 10522)

Required when using electrical actuators

Installation example:

+49 (0) 2764 261 35 - 0

+49 (0) 2764 261 35 - 20